The Efficiency of an Optical Fibre Diameter Analyser in Reducing Manufacturing Errors

The Efficiency of an Optical Fibre Diameter Analyser in Reducing Manufacturing Errors

Blog Article

Just How an Optical Fibre Diameter Analyser Improves High Quality Control in Fibre Manufacturing

The combination of an Optical Fibre Diameter Analyser into Fibre production processes stands for a substantial improvement in quality control techniques. By offering real-time, accurate measurements of Fibre diameters, this technology addresses the essential requirement for uniformity in manufacturing requirements.

Importance of Fibre Diameter Dimension

Accurate measurement of Fibre Diameter is crucial in the field of optical Fibre modern technology, as it directly affects the efficiency and integrity of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying ability, attenuation, and total transmission efficiency. Accuracy in determining Fibre Diameter ensures that the optical buildings are maintained within defined tolerances, which is crucial for optimum signal stability.

Variations in Fibre Diameter can bring about enhanced losses due to spreading and modal diffusion, impacting the quality of data transmission. In high-speed interaction systems, such discrepancies can lead to substantial degradation of signal top quality, bring about data mistakes and lowered efficiency. Moreover, regular Fibre Diameter is essential for compatibility with connectors and splicing innovations, which are essential parts of Fibre optic networks.

Quality control procedures in Fibre production heavily count on accurate Diameter dimensions to make sure conformity with industry requirements. By executing durable dimension techniques, makers can boost product reliability, lessen waste, and enhance general system efficiency. Therefore, the value of Fibre Diameter measurement can not be overstated, as it acts as a foundation in the improvement of optical Fibre technology and its applications in modern interaction networks.

Exactly How the Analyser Functions

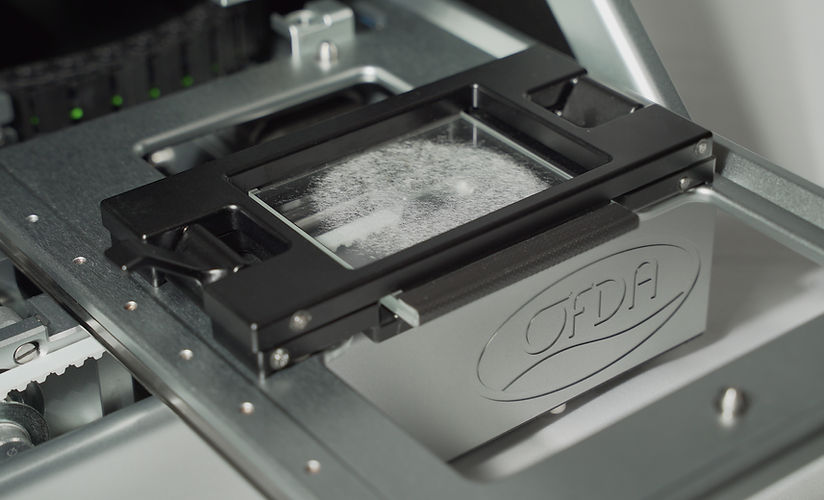

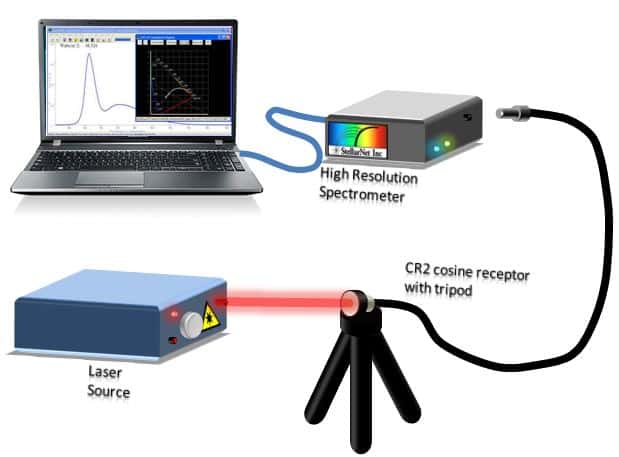

The reliable dimension of Fibre Diameter relies upon sophisticated logical techniques that make certain accuracy and integrity in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser employs a mix of laser modern technology and advanced image processing formulas to properly examine the Diameter of fibers as they are generated

Initially, a laser beam of light is guided at the moving Fibre, producing a cross-sectional darkness. The analyser records this darkness utilizing high-resolution cams positioned tactically along the production line. The recorded images are then processed in real-time to identify the Fibre's Diameter with remarkable accuracy.

The system utilizes advanced algorithms that account for numerous elements, including variations in light strength and ecological conditions, to boost measurement dependability. It can detect minute adjustments in Diameter, such as variations that might happen during the manufacturing process.

Moreover, the analyser can managing numerous fibres concurrently, enhancing throughput without endangering precision. By offering instantaneous feedback on the Diameter, the Optical Fibre Diameter Analyser plays a critical function in keeping rigid high quality control requirements, making certain that the last product meets industry specifications and client demands.

Benefits of Real-Time Surveillance

While typical techniques of monitoring Fibre Diameter usually involve taxing post-production checks, real-time tracking considerably boosts the performance and top quality of optical Fibre production. optical fibre diameter analyser. This aggressive strategy enables manufacturers to recognize variances in Fibre Diameter as they take place, instead of waiting until production is complete to evaluate high quality

By continually determining the Diameter during manufacturing, makers can make sure that the fibres meet strict specs, bring about decreased irregularity and boosted uniformity. Real-time monitoring additionally allows prompt restorative activities to be taken, minimizing waste and avoiding faulty fibres from entering the supply chain.

Moreover, this modern technology click reference facilitates enhanced information collection and evaluation, supplying understandings right into production fads and possible areas for improvement. Such data-driven decision-making empowers manufacturers to enhance procedures and keep high requirements of quality assurance.

Furthermore, real-time tracking fosters a society of continual improvement within the production setting. Staff members are a lot more involved when they can see the effect of their job in real-time, leading to heightened liability and a commitment to excellence. Generally, the execution of real-time tracking systems in optical Fibre production converts to premium item high quality and boosted consumer satisfaction.

Effect On Production Performance

Executing optical Fibre Diameter analysers dramatically enhances production efficiency by simplifying the production procedure. These devices facilitate constant monitoring of Fibre Diameter, allowing producers to spot inconsistencies in real-time. By determining inconsistencies promptly, assembly line can be adjusted promptly, lessening downtime and decreasing the likelihood of generating faulty products.

Moreover, the combination of these analysers into the production workflow makes it possible for better source allowance. With accurate Diameter dimensions, drivers can enhance product use, making certain that resources are not lost on mistaken fibres. This accuracy additionally adds to less remodel and ditch, eventually reducing manufacturing prices.

The automation given by optical Fibre Diameter analysers reduces dependence on hands-on assessments, which are susceptible and usually lengthy to human error. As a result, employees can concentrate on even more calculated tasks, improving overall efficiency.

In addition, the information created from these analysers can notify procedure improvements and help with better decision-making. By assessing trends in Fibre Diameter variants, suppliers can carry he said out aggressive actions to boost manufacturing methods and preserve consistent top quality. In summary, optical Fibre Diameter analysers play a vital role in improving production performance, bring about better output and raised success.

Study and Success Stories

Across different fields, situation studies highlight the transformative influence of optical Fibre Diameter analysers on manufacturing processes. One popular example is a leading telecoms business that encountered obstacles with irregular Fibre diameters, bring about enhanced being rejected prices. By incorporating an optical Fibre Diameter analyser, the firm accomplished real-time surveillance of Fibre measurements, leading to a 30% reduction in flaws and significant price savings.

Additionally, a research study institution concentrating on advanced materials utilized optical Fibre Diameter analysers to refine their speculative processes. The analyser's capacity to offer detailed understandings into Fibre consistency enabled the advancement of cutting-edge products with enhanced performance features.

These success stories underscore the essential function of optical Fibre Diameter analysers in improving high quality control, improving production performance, and driving innovation throughout varied industries.

Conclusion

In conclusion, the Optical Fibre Diameter Analyser plays a crucial function in boosting high quality control within Fibre production. As demonstrated via various case researches, the analyser site confirms vital for achieving superior product top quality in Fibre production.

The implementation of optical Fibre Diameter analysers enabled for rigorous high quality control, making sure that the produced fibers met exacting market criteria.In final thought, the Optical Fibre Diameter Analyser plays a pivotal role in enhancing quality control within Fibre manufacturing.

Report this page